| Product Classification |

Add: Add:

- Room 1801-1803, Jinmao international building, Nanchang Road, Jianxi District, Luoyang, Henan, China

- Tel:(0379)65198226

65198229

- Email:13803790795@139.com

- http://www.lyvenus.net

|

|

|

|

|

| LDK Air Plasma Spheroidizing Furnace |

|

Product Information |

|

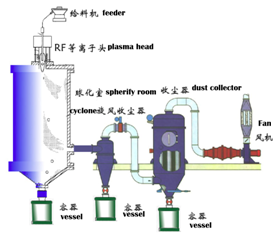

It is applied to the fine powder densification and spheroidization, and it is generally used for heating and fusing the materials that fed in the form of particles or micro powder. Therefore, the formed fused spherical bubble gradually cooled under the free -fall condition. According to the particle size and the processed powder surface density, we can control the time of the fluid body, before the fused bubble arrived at the bottom of the first reactor vessel box, it has enough time to be completely solidificated. The fine particles that inhaled by the plasma were collected by the downstream filter screen of the first vessel box.

Improved the flowing property of powder;When feeding, the flowing speed of the spheroidizing processed particulate will be more consistent;Reduced the powder porousness: After the material fused, the holes would be eliminated, such material can be better applied to the metallurgy application and the density packaging;Increased the powder density: With the increasement of the spherical powder, the whole particle density will increase;Reduced the powder friability: Its local or superficial abrasion will be greatly reduced,by reducing the used powder side, losing skin, surface defects or rupture before processing. Such treatment removed the internal rupture or the brittle internal adhesion, the ultimate effect is to make the cladding part keep longer wear resistance life;Improved the surface glossiness of fine particle: The sharp angle of the single fine particle can be eliminated, by improving the micro smooth grade, the high magnified surface will be more smooth. Such situation is more beneficial to the low requirement of the friction coefficient. Some non-spherical fine powder of the gas transmission can produce great abrasion, this will lead to the pollution and the constant parts replacement. The more smooth surface only in the production pigment mixed place can reduce its mutability;Improved the micro powder purity: The fluid body fusion process can better improve the micro powder purity, which formed by the special impurity selectivity and the to-and-fro evaporation. |

| Specification |

.png) |

|

|